How to replace the LED backlight strip of TV LCD

LCD TV backlight method produced in recent years is almost all LED backlight. Nowadays, the backlight of LED LCD TV has entered the peak of maintenance, especially in the last two years of television sets, the failure rate of LED backlight strip is particularly high.

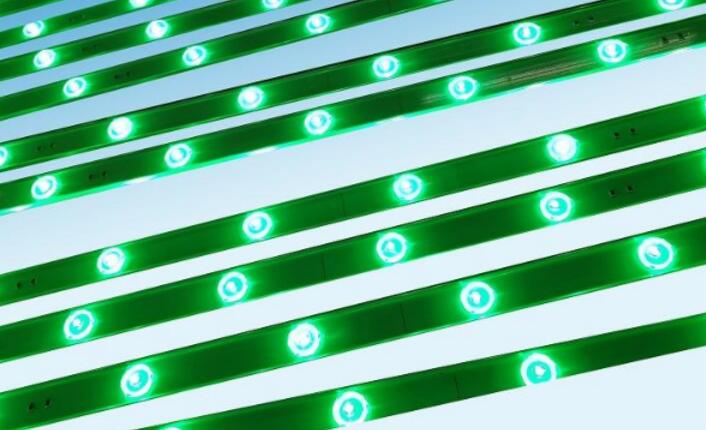

LED strip features

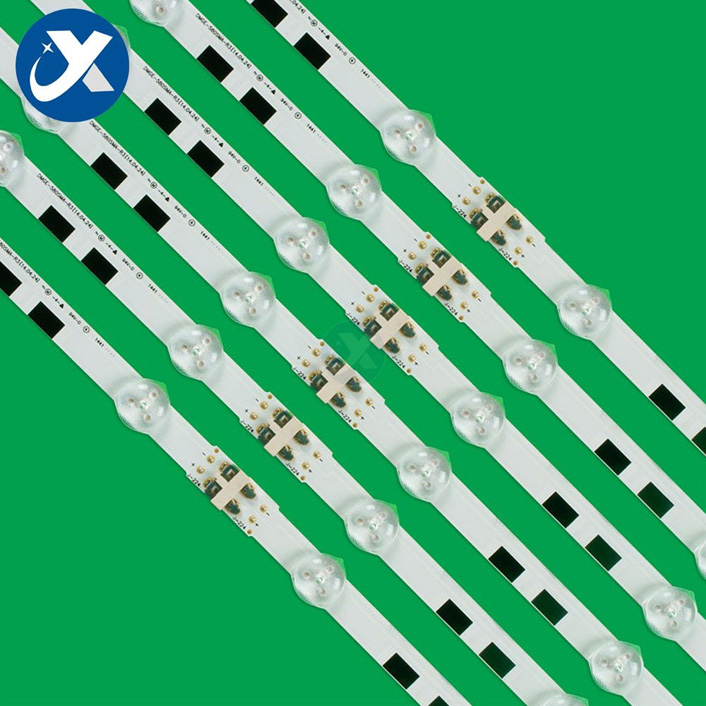

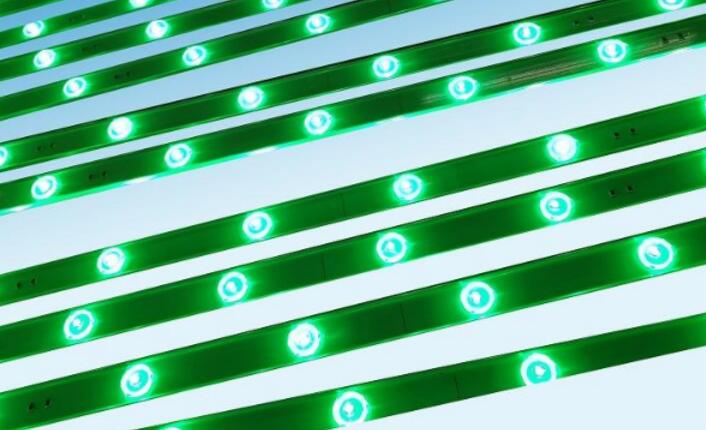

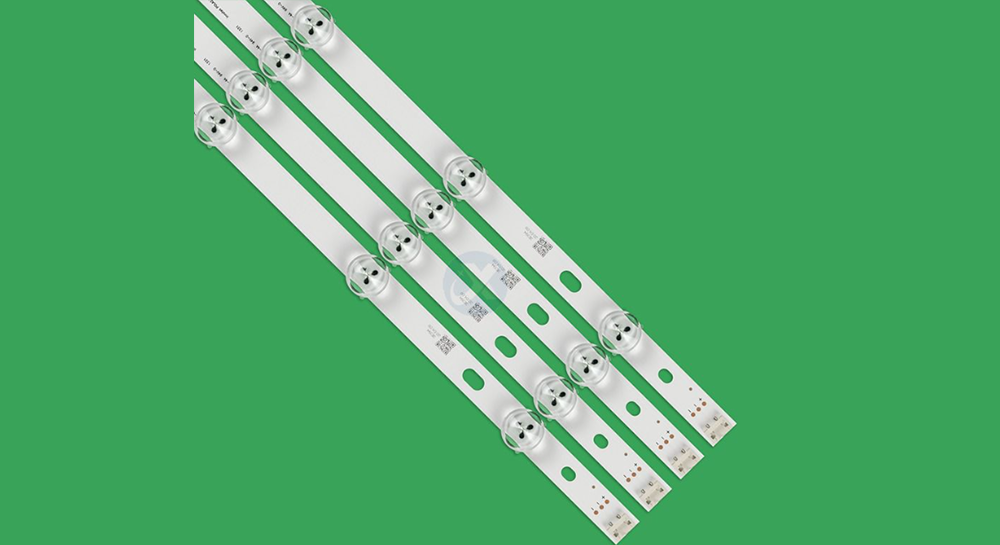

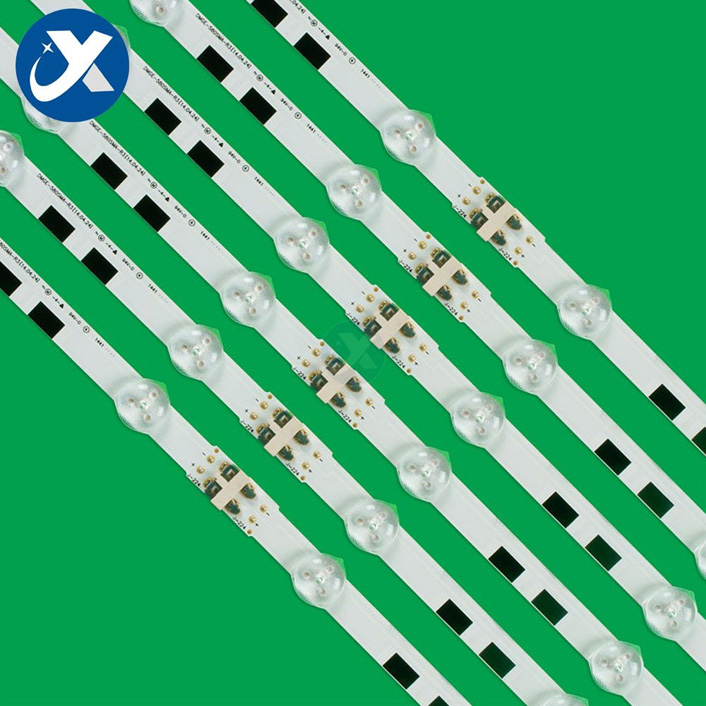

LED LCD backlight has multiple groups of LED lights. The backlight is divided into two types of irradiation, slightly different structure: one is the back transparent direct down type, the light source is installed directly on the back of the LCD panel, LED lights directly irradiate the LCD panel. This method often has 4 groups, 6 groups or more groups of LED lights. The second is the side-transparent type. The light source is installed on the side of the thick light guide plate. This method often has one or two groups of LED lights. The arrangement of the two types of backlighting is different.

The performance and parameters of several groups of LED lights on the same screen are the same. Each group of LED lights consists of several LED beads, and each LED unit is assembled on a metal strip by a press welding process. Each group consists of multiple LED beads connected in series. How to distinguish whether all the LED beads on an LED strip are connected in series or in segments in series? One is to look at the power socket on the metal strip, and one is to look at the numbers on the metal strip. If there are only two pins in the socket, it means that all the LED beads on this strip are connected in series. If there are only three pins in the socket, it means that the LED beads on this strip are connected in series in two groups. Another way to differentiate is by the number marked on the beads on the strip. Regular light bars have numbers on the edges of the LED beads. For example, if the total number of beads on a strip is 52 LEDs, and the number marked is from "1" to "52", it means 52 LEDs are connected in series. For example, if there are 60 LEDs on a light bar, the numbers marked from "1" to "20" are "1" to "20" respectively. "20" means that 20 capsules are connected in series to form a group, a total of 3 groups.

Each light bead on a normal light bar is powered by 3.2V. How many light beads on a light bar, divided into how many light beads for a group, so that you can accurately calculate the power supply voltage. For example, two light bars have completely different models, but the length of the light bar and the power supply interface are the same. Whether they can be replaced, we need to use the method described above to calculate the supply voltage and check whether the lamp bead current is consistent.

How to replace the TV LCD LED backlight strip

First, replace the lamp or LED light bar as follows.

① → Although the failure rate of LCD color TV lamp or LED strip is not high, aging, fire or damage happens from time to time. If the lamp or LED strip is confirmed to be abnormal, the LCD should be removed when repairing or replacing it. Due to the fragility of the LCD panel, the LCD panel internal structure is precise and requires careful operation in accordance with certain steps when disassembling.

Second, the lamp replacement instructions.

①→ Strictly speaking, the whole operation process of replacing the lamp or LED strip should be carried out in a dust-free environment. The actual operation should be carried out as far as possible in an environment with little dust or with dust control measures. If possible, you can borrow a glass cabinet and use its clean interior space for cleaning

surgery.

② → Clean white gloves must be worn during operation to prevent hands from being left on the LCD panel or leveling assembly

fingerprints.

③ → The removed screws should be sorted and marked to prevent mistakes during installation.

④ → The workbench must be covered with a clean soft cloth or sponge pad to protect the LCD panel.

⑤ → Before installing the LCD module, the surface should be dusted. Replace the lamp need to prepare the following tools: a small one-word screwdriver and small cross screwdriver, a pair of rubber gloves, hard thin plastic sheet <such as cell phone number card and scrap bank card>, new lamp or LED strip, several diameter of 1.5mm, 2mm and 4mm heat shrinkable sleeve, sponge pad, dust-free cloth, needle <or needle>, tweezers, tape paper, soldering iron, anti-static hand ring, and so on

LED TV LCD light bar maintenance methods

After confirming the LCD light bar damage, first remove the screen, and then start the TV to see if the backlight bar on the light beads do not light. After confirming the failure point, remove the light strip for maintenance. If you find a group of LED lights do not light up, use the pointer multimeter rxlok file to measure the resistance value at both ends of each diode, so as to determine which LED is bad.

Under normal circumstances, each diode has a resistance of several tens of thousands of ohms at both ends and will glow. Across two or three of the actual measurement will also be very bright, but the brightness is much darker. However, some diodes have high operating voltage at both ends (4a-lcd55t-ss1 screen LED unit operating voltage of 6.5V). When measured with the diode block of the digital meter, the LED bulb does not light up, but the rx10k block of the pointer multimeter will light up. If all diodes on a light strip are not lit when measured, the light strip should be considered to be using high voltage lamp beads, because the lamp beads on the strip will not be damaged at the same time.

In addition to the light strip printing board and the metal part of the back of the strip leakage, short circuit, you can use the method of replacing the LED bulb after the LED bulb is damaged, but the premise is that it must be equipped with the same type of LED bulb and requires a soldering station, air gun and other tools. The actual replacement should be properly handled when the LED lamp beads heat dissipation, otherwise it will affect the service life of the LED lamp beads.

If only one LED bulb on the strip is damaged due to open circuit, it can also be repaired by short-circuiting, i.e., using thin copper wire to short-circuit the pads at both ends of the bulb, or picking out the protective film (yellow sealant) with pointed tweezers on the LED bulb, using solder to short the positive metal disk and negative metal disk inside the LED.

If multiple LED beads on a light bar are damaged due to open circuit and short circuit, the naked eye can see the bad beads. If the middle part of the LED bead sealer is blackened, it is generally damaged. If multiple LED beads are damaged, they must be removed and replaced. If more than one LED bead is short-circuited, it will inevitably cause startup protection.

How to distinguish the LED strip leakage or short circuit? Use a multimeter to measure the resistance between the pins in the light bar power plug-in and the aluminum plate on the back of the light bar. The normal resistance value is infinity. If there is leakage or short circuit, replace the LED strip or assembly with heat sink of the same model.

LED strip light replacement instructions

The easiest way is to directly replace the same type of LED strip or assembly with a heatsink, but it is difficult to find the same type of LED assembly or strip even though it is expensive.

My repair experience is to buy a variety of LED LCD crusher, remove the light strip as spare parts, eliminate the trouble of LED lamp beads out of stock, take the removed strip to practice welding, master the air temperature and skills when removing and replacing the gun. Replace the light strip does have a certain risk. We must negotiate a good price before repair. Be careful when dismantling and installing the LCD, the LCD should not be placed for too long. Placement should be safe to prevent damage caused by accidental collision.